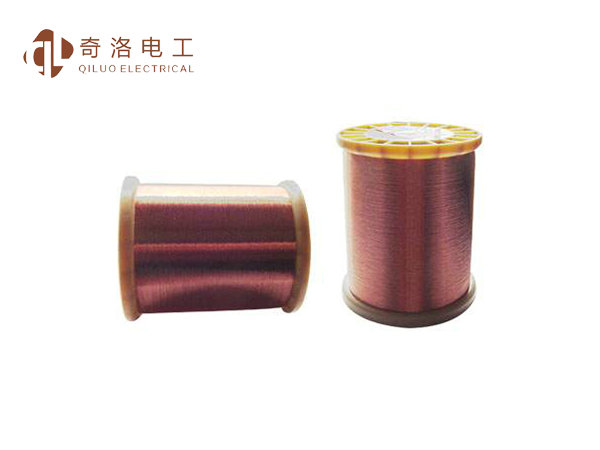

Detail and application hazard of aluminum enameled wire

- Release time:2020-04-29

- Publisher: baidu baike

- source: baidu baike

- Reading:

1, copper to aluminum details

(a) change of wire diameter (due to difference of conductor resistivity)

Aluminum wire diameter = copper wire diameter 1.28

(b) planned alteration of slot (diameter difference)

Is the resistance of the original conductor, thus resulting in an increase in the conductor wire diameter, as well as an increase in the slot full rate at a certain level.

(c) changes in winding (difference in tensile strength)

Aluminum is less ductile than copper, so it is necessary to low winding tension, should be low winding speed

(d) change in method of joining (difference in brazing properties)

Compared with copper, aluminum is very easy to oxidize, welding is very difficult to accept the original copper wire welding process and material, on the tin base is not about, in order to be adjacent must accept aluminum enameled wire special solder material and process.

2, copper to aluminum skill key

In terms of their aluminum enameled wire, and copper than force is resistivity difference, to change is copper aluminum enameled wire, as long as according to the resistivity than the wire diameter of aluminium wire, aluminum wire in all aspects such as temperature, current, energy efficiency will not worse than copper wire, is to plan, the copper grade aluminum without problems, but because of the metal aluminium extremely live wave, easy oxidation, the tin is difficult, many enterprises very headache about this subject. With the application of aluminum enameled wire the key depends on how to deal with the problem of adjacent point welding.

3, about the aluminum wire welding, recently I have to zhejiang, zhongshan, sichuan, Qingdao, hebei and other places to see a lot of manufacturers using the aluminum wire environment, the effective terminal riveting, effective solder wire welding, also some easy to copper lead to aluminum wire wrapped welding and so on. Tell the truth, there are few companies with good punishment for welding treatment of aluminum enameled wire in China, and the detailed welding of aluminum enameled wire should be divided into two processes: one is to remove paint, the other is to weld.

(A) take off paint, now there are many factories with high temperature tin hot, hot after the aluminum wire will become yellow, black edge, on the basis of the solder, some use take off paint machine, due to the report of friction, the temperature is very high, to take off paint aluminum wire on the one hand diameter damage, on the other hand aluminum wire appearance black, severe oxidation, also very difficult to tin.

(B) the method of connecting the first terminal riveting, aluminum wire oxidation is fast, the potential difference between other copper and aluminum is large, the electrification process will be sure to gradually incubate potential decay, the adjacent point resistance will gradually become larger, the temperature rise becomes higher, the end is sure to lack of good electricity.

Solder wire welding also is to have goals, the temperature of the soldering iron not very big, about to sound is easy to produce false surfacing welding, appearance looks very full, just inner, encase, other flux evaporative loss no measures for short periods of time, is to solder joint inside there will be many coking flux residues, through argument is not by this method.

Copper lead package aluminum welding, this method is self-deception, just the appearance of copper on tin, the aluminum base inside the package is not on tin, think about how sharp the problem is.

(a) change of wire diameter (due to difference of conductor resistivity)

Aluminum wire diameter = copper wire diameter 1.28

(b) planned alteration of slot (diameter difference)

Is the resistance of the original conductor, thus resulting in an increase in the conductor wire diameter, as well as an increase in the slot full rate at a certain level.

(c) changes in winding (difference in tensile strength)

Aluminum is less ductile than copper, so it is necessary to low winding tension, should be low winding speed

(d) change in method of joining (difference in brazing properties)

Compared with copper, aluminum is very easy to oxidize, welding is very difficult to accept the original copper wire welding process and material, on the tin base is not about, in order to be adjacent must accept aluminum enameled wire special solder material and process.

2, copper to aluminum skill key

In terms of their aluminum enameled wire, and copper than force is resistivity difference, to change is copper aluminum enameled wire, as long as according to the resistivity than the wire diameter of aluminium wire, aluminum wire in all aspects such as temperature, current, energy efficiency will not worse than copper wire, is to plan, the copper grade aluminum without problems, but because of the metal aluminium extremely live wave, easy oxidation, the tin is difficult, many enterprises very headache about this subject. With the application of aluminum enameled wire the key depends on how to deal with the problem of adjacent point welding.

3, about the aluminum wire welding, recently I have to zhejiang, zhongshan, sichuan, Qingdao, hebei and other places to see a lot of manufacturers using the aluminum wire environment, the effective terminal riveting, effective solder wire welding, also some easy to copper lead to aluminum wire wrapped welding and so on. Tell the truth, there are few companies with good punishment for welding treatment of aluminum enameled wire in China, and the detailed welding of aluminum enameled wire should be divided into two processes: one is to remove paint, the other is to weld.

(A) take off paint, now there are many factories with high temperature tin hot, hot after the aluminum wire will become yellow, black edge, on the basis of the solder, some use take off paint machine, due to the report of friction, the temperature is very high, to take off paint aluminum wire on the one hand diameter damage, on the other hand aluminum wire appearance black, severe oxidation, also very difficult to tin.

(B) the method of connecting the first terminal riveting, aluminum wire oxidation is fast, the potential difference between other copper and aluminum is large, the electrification process will be sure to gradually incubate potential decay, the adjacent point resistance will gradually become larger, the temperature rise becomes higher, the end is sure to lack of good electricity.

Solder wire welding also is to have goals, the temperature of the soldering iron not very big, about to sound is easy to produce false surfacing welding, appearance looks very full, just inner, encase, other flux evaporative loss no measures for short periods of time, is to solder joint inside there will be many coking flux residues, through argument is not by this method.

Copper lead package aluminum welding, this method is self-deception, just the appearance of copper on tin, the aluminum base inside the package is not on tin, think about how sharp the problem is.