What are the classifications of enameled wire

- Release time:2020-04-29

- Publisher: baidu baike

- source: baidu baike

- Reading:

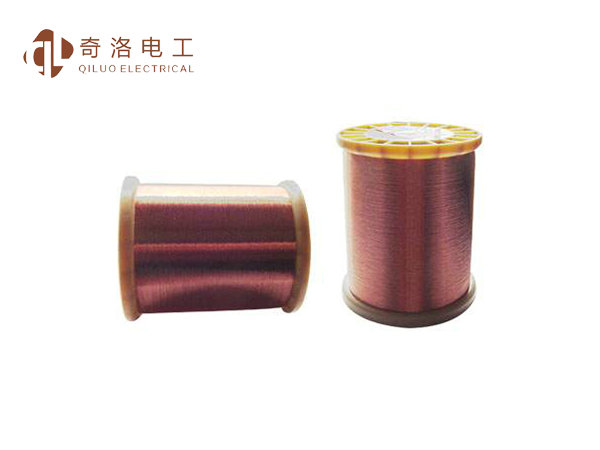

Enameled wire is the main raw material of electrical machinery, electrical appliances and household appliances. Especially in recent years, the electric power industry has achieved a sustained and rapid growth, and the rapid development of household appliances has brought a broader range of applications to enameled wire, followed by a higher requirement for enameled wire. Therefore, it is inevitable to adjust the product structure of enameled wire, and the raw materials (copper, lacquer), enameled coating process, process equipment and detection means are also in urgent need of development and research, and there are more categories, details are as follows:

1) acetal enameled wire

Acetal enamelled wire is one of the earliest developed varieties in the world. In 1930, it was put into the market by Germany and the United States respectively. The Soviet union also developed quickly. Although the enameled wire has low temperature resistance grade (105°C, 120°C), it is widely used in oil-immersed transformers because of its excellent high-temperature hydrolysis resistance performance, which has been notarized by all countries in the world.

2) polyester enameled wire

In the 1950s by west Germany, the first successful development of polyester enameled wire paint based on dimethyl terephthalate, due to its good heat resistance and mechanical strength, wide range of paint process, low price, from the 1950s has become the dominant enameled wire market main products. However, due to the poor thermal shock resistance of polyester enameled wire, in high temperature, high humidity conditions easy to hydrolyze and other reasons, the late 1970s as a single coating of polyester enameled wire in west Germany and the United States has been no longer produced, and in Japan, China and southeast Asia is still a large number of production and use. Statistics in 1986 show that China's output of polyester enameled wire accounted for 96.4% of the total output. After 10 years of efforts, the variety of enameled wire has been developed, but there is a big gap with developed countries [1].

A lot of work has been done on the modification of polyester in China. THEIC modification and imine modification have been researched and developed. However, due to the slow structural adjustment of enameled wire, the production of these two paints is still not large. Up to now, the voltage drop of the modified polyester enameled wire still needs attention.

3) polyurethane enameled wire

Polyurethane enameled wire paint was developed by bayer in Germany in 1937. It is widely used in the fields of electronics and electrical appliances because of its direct weldability, high frequency resistance and dyeability. At present, foreign countries pay great attention to improving the heat resistance grade of polyurethane enameled wire without affecting its direct welding performance. In Europe, the United States, Japan has developed F - class, H - class polyurethane enameled wire. Due to the rapid development of color TV, the color TV FBT developed by Japan has attracted the attention of all countries in the world by using the polyurethane enameled wire with long length and no brine pinhole, and is still Japan's leader [1].

The development of domestic polyurethane enameled wire is slow, although common polyurethane paint has a few factories to produce, but because craft is poor, the problem such as surface quality, because this paint basically still depends on import. F-grade polyurethane has also been developed in China, but no production capacity has been formed. Large length non-pinhole polyurethane paint has also been successfully developed and marketed for the production of black and white television FBT coils.

4) polyester imide enameled wire

Since the 1970s, the amount of poly-imide enameled wire in the world has risen sharply. In Europe and the United States, this enameled wire has completely replaced the single coated poly-enameled wire. At present, the TerebeFH series products from Germany and Isomid series products from the United States are representative in the world. At the same time, directly welded polyester-imide enameled wire has been developed, which has been widely used as the winding of small motor, which simplifies the welding process and reduces the manufacturing cost of motor. Some Japanese also use direct welding polyester imide paint as color TV deflection coil with self - adhesive enameled wire primer, simplified the process. Domestic polyester imide paint has been introduced from Germany and Italy manufacturing technology, there are also their own development of success, but due to the instability of raw materials and other reasons, currently a large number of domestic polyester imide paint used as antifreeze compound enameled wire primer is still dependent on imports. Only a small number of single-coated polyester-imide enameled wires are applied with domestic paint, but the unstable voltage is still a concern of the manufacturer.

5) polyimide enameled wire

Polyimide is the highest heat-resistant enameled wire paint in organic enameled wire, and its long-term temperature can reach more than 220°C. The paint was developed by the United States in 1958. Polyimide enameled wire has high heat resistance, good solvent and refrigerant resistance. However, due to its high cost, poor storage stability and toxicity, it is not widely used. At present, the enameled wire is used for some special occasions, such as coal mine motor, space instruments and other wires.

6) polyamideimide paint

Polyamideimide paint is the present enameled wire paint performance is more comprehensive, with high heat resistance, mechanical properties, refrigerant resistance and chemical resistance, so it is the king of enameled wire paint. At present, the paint is mainly used for its unique properties, widely used as the finish coat of the composite coating enameled wire, improve the heat resistance of the composite wire and reduce the cost. At present, it is mainly used to coat freeze-resistant enameled wire in China. The paint is produced in a small quantity in China and mainly imported from the United States, Italy and Germany.

7) compound coated enameled wire

To improve the temperature resistance grade and develop enameled wire for special purpose, composite insulation layer is generally used. Compared with single coated enameled wire, composite coated enameled wire has the following advantages :(1) it can meet the special requirements, such as self-adhesive enameled wire for complex bindless forming, and freeze-resistant enameled wire for refrigerators and air conditioning compressors. (2) through the combination of various insulation layers to make its characteristics from each other, improve and improve the performance, in order to meet the use requirements, such as polyester/nylon composite coating enameled wire to improve the thermal shock performance and winding performance, suitable for the thermal impregnation process, for the overload caused by the instantaneous overheating of the motor winding; (3) can reduce the cost of some enameled wire, such as polyester imide, polyamideimide composite coating enameled wire instead of a single coating of polyamideimide enameled wire, can significantly reduce the cost.

1) acetal enameled wire

Acetal enamelled wire is one of the earliest developed varieties in the world. In 1930, it was put into the market by Germany and the United States respectively. The Soviet union also developed quickly. Although the enameled wire has low temperature resistance grade (105°C, 120°C), it is widely used in oil-immersed transformers because of its excellent high-temperature hydrolysis resistance performance, which has been notarized by all countries in the world.

2) polyester enameled wire

In the 1950s by west Germany, the first successful development of polyester enameled wire paint based on dimethyl terephthalate, due to its good heat resistance and mechanical strength, wide range of paint process, low price, from the 1950s has become the dominant enameled wire market main products. However, due to the poor thermal shock resistance of polyester enameled wire, in high temperature, high humidity conditions easy to hydrolyze and other reasons, the late 1970s as a single coating of polyester enameled wire in west Germany and the United States has been no longer produced, and in Japan, China and southeast Asia is still a large number of production and use. Statistics in 1986 show that China's output of polyester enameled wire accounted for 96.4% of the total output. After 10 years of efforts, the variety of enameled wire has been developed, but there is a big gap with developed countries [1].

A lot of work has been done on the modification of polyester in China. THEIC modification and imine modification have been researched and developed. However, due to the slow structural adjustment of enameled wire, the production of these two paints is still not large. Up to now, the voltage drop of the modified polyester enameled wire still needs attention.

3) polyurethane enameled wire

Polyurethane enameled wire paint was developed by bayer in Germany in 1937. It is widely used in the fields of electronics and electrical appliances because of its direct weldability, high frequency resistance and dyeability. At present, foreign countries pay great attention to improving the heat resistance grade of polyurethane enameled wire without affecting its direct welding performance. In Europe, the United States, Japan has developed F - class, H - class polyurethane enameled wire. Due to the rapid development of color TV, the color TV FBT developed by Japan has attracted the attention of all countries in the world by using the polyurethane enameled wire with long length and no brine pinhole, and is still Japan's leader [1].

The development of domestic polyurethane enameled wire is slow, although common polyurethane paint has a few factories to produce, but because craft is poor, the problem such as surface quality, because this paint basically still depends on import. F-grade polyurethane has also been developed in China, but no production capacity has been formed. Large length non-pinhole polyurethane paint has also been successfully developed and marketed for the production of black and white television FBT coils.

4) polyester imide enameled wire

Since the 1970s, the amount of poly-imide enameled wire in the world has risen sharply. In Europe and the United States, this enameled wire has completely replaced the single coated poly-enameled wire. At present, the TerebeFH series products from Germany and Isomid series products from the United States are representative in the world. At the same time, directly welded polyester-imide enameled wire has been developed, which has been widely used as the winding of small motor, which simplifies the welding process and reduces the manufacturing cost of motor. Some Japanese also use direct welding polyester imide paint as color TV deflection coil with self - adhesive enameled wire primer, simplified the process. Domestic polyester imide paint has been introduced from Germany and Italy manufacturing technology, there are also their own development of success, but due to the instability of raw materials and other reasons, currently a large number of domestic polyester imide paint used as antifreeze compound enameled wire primer is still dependent on imports. Only a small number of single-coated polyester-imide enameled wires are applied with domestic paint, but the unstable voltage is still a concern of the manufacturer.

5) polyimide enameled wire

Polyimide is the highest heat-resistant enameled wire paint in organic enameled wire, and its long-term temperature can reach more than 220°C. The paint was developed by the United States in 1958. Polyimide enameled wire has high heat resistance, good solvent and refrigerant resistance. However, due to its high cost, poor storage stability and toxicity, it is not widely used. At present, the enameled wire is used for some special occasions, such as coal mine motor, space instruments and other wires.

6) polyamideimide paint

Polyamideimide paint is the present enameled wire paint performance is more comprehensive, with high heat resistance, mechanical properties, refrigerant resistance and chemical resistance, so it is the king of enameled wire paint. At present, the paint is mainly used for its unique properties, widely used as the finish coat of the composite coating enameled wire, improve the heat resistance of the composite wire and reduce the cost. At present, it is mainly used to coat freeze-resistant enameled wire in China. The paint is produced in a small quantity in China and mainly imported from the United States, Italy and Germany.

7) compound coated enameled wire

To improve the temperature resistance grade and develop enameled wire for special purpose, composite insulation layer is generally used. Compared with single coated enameled wire, composite coated enameled wire has the following advantages :(1) it can meet the special requirements, such as self-adhesive enameled wire for complex bindless forming, and freeze-resistant enameled wire for refrigerators and air conditioning compressors. (2) through the combination of various insulation layers to make its characteristics from each other, improve and improve the performance, in order to meet the use requirements, such as polyester/nylon composite coating enameled wire to improve the thermal shock performance and winding performance, suitable for the thermal impregnation process, for the overload caused by the instantaneous overheating of the motor winding; (3) can reduce the cost of some enameled wire, such as polyester imide, polyamideimide composite coating enameled wire instead of a single coating of polyamideimide enameled wire, can significantly reduce the cost.